Amphenol Aerospace

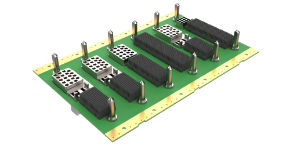

R-VPX VITA 46 Backplane Connectors

Amphenol’s R-VPX VITA 46 Connector System is a ruggedized, high-speed, board-to-board interconnect system capable of data rate speeds of more than 10 Gb/s, meeting and exceeding VITA 46 standards. This connector system gives users modularity and flexibility via PCB wafer construction allowing for customized wafer-loading patterns.

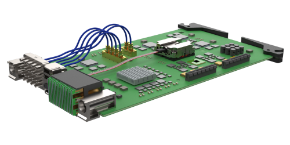

R-VPX VITA 46 Plugin Connectors

Amphenol’s R-VPX VITA 46 Connector System is a ruggedized, high-speed, board-to-board interconnect system capable of data rate speeds of more than 10 Gb/s, meeting and exceeding VITA 46 standards. This connector system gives users modularity and flexibility via PCB wafer construction allowing for customized wafer-loading patterns.

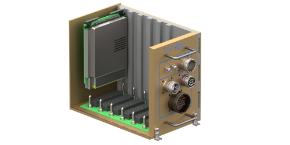

MIL-HD2 VITA 91 Backplane Connectors

Developed in alignment with The Open Group Sensor Open Systems Architecture™ (SOSA) technical standard, MIL-HD2 provides developers with a readily available, robust open architecture solution for tighter card pitches and chassis designs where space requirements and density are critical. These connectors are available in 3-, 4-, and 6-pair configurations, providing the MIL-embedded market with the highest count of differential pairs available today in a 3U configuration at 56Gb/s PAM 4 speeds. This series was selected by the SOSA Consortium and provides a SOSA aligned solution for nextgen switch and payload card requirements enabling the MIL-embedded market to meet next-gen performance levels while still meeting COTS requirements.

MIL-HD2 VITA 91 Plugin Connectors

Developed in alignment with The Open Group Sensor Open Systems Architecture™ (SOSA) technical standard, MIL-HD2 provides developers with a readily available, robust open architecture solution for tighter card pitches and chassis designs where space requirements and density are critical. These connectors are available in 3-, 4-, and 6-pair configurations, providing the MIL-embedded market with the highest count of differential pairs available today in a 3U configuration at 56Gb/s PAM 4 speeds. This series was selected by the SOSA Consortium and provides a SOSA aligned solution for nextgen switch and payload card requirements enabling the MIL-embedded market to meet next-gen performance levels while still meeting COTS requirements.

LEAP OBT Socket

10140369-201LF

The LEAP® OBT socket has been designed to host the LEAP OBT optical modules (standard & rugged). The socket is soldered onto the PCB. The socket is soldered via the corner solder pads and the electrical interfaces consists of 225 BGA solder balls. LEAP OBT is then mounted on top of the socket with 4 screws and the electrical interfaces are ensured via the 225 LGA spring contacts.